Magnetic drums from IPES International of Pittsburgh come in a variety of sizes and strengths to suit a customer’s needs. These drums are used to extract ferrous materials from a high throughput product stream of dry, bulk products in free-flowing processing systems.

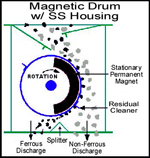

Thanks to a stationary permanent magnet made of Ceramic-8A or Rare Earth Neodymium (which is five times stronger than Ceramic-8 and can remove micron-sized particles) enclosed in a non-magnetic stainless-steel drum, product flows across the surface of the rotating drum with ferrous matter drawn to the drum’s surface. It gets held against it by the magnet housed inside.

Since the ferrous metal clings to the drum’s surface and non-ferrous products fall from the side of the drum in a normal manner, the ferrous particles can then fall from the drum into a collection container (due to a reduction in the magnetic field) as the ferrous material rotates to the side opposite the product flow.

Magnetic drums are used by a wide variety of companies to get cleaned, filtered product, free of ferrous material.

IPES International can provide the drum only, or complete units with the housing and drive included. Magnetic drums are used for minerals processing, as well as chemical processing. In addition, the pharmaceutical and food processing industries use drums for their processes. Specifically, magnetic drums are used to remove ferrous particles from glass cullet, powder/granular materials, and foodstuffs, among other applications.

To discuss your magnetic drum needs, call IPES International at 412-781-4660. The company offers products of superior quality, durability, and performance, guaranteed.